Food Quality and Safety

Food quality and safety are fundamental and highly relevant aspects in the development of the Freixenet’s Group productive activity. This article details the demanding measures that the company carries out throughout the manufacturing process of its products to ensure the highest quality and food safety. The high standards offered by the Freixenet group in these fields are the result of the company’s commitment to innovation, science and cutting-edge technology. Manel Quintana, head of Oenology at the Freixenet Group and Jaume Martín, Head of Quality of the company, give us their testimony in this regard.

ENOLOGY, MICROBIOLOGICAL DRAIN.

MANEL QUINTANA, RESPONSIBLE FOR OENOLOGY OF GRUPO FREIXENET

The Freixenet Group works hard with the aim that the product is unique and stands out for its uniqueness. For this reason, native yeasts from the Penedes vineyards selected by the company itself are used. In other words, the Freixenet Group has its own yeast cultures with exceptional oenological properties that have been maintained for decades thanks to research and scientific commitment. Thus, wines are made with a special bouquet and with aromas that adapt to consumer tastes. The method used by the company is a rare method among companies in the sector.

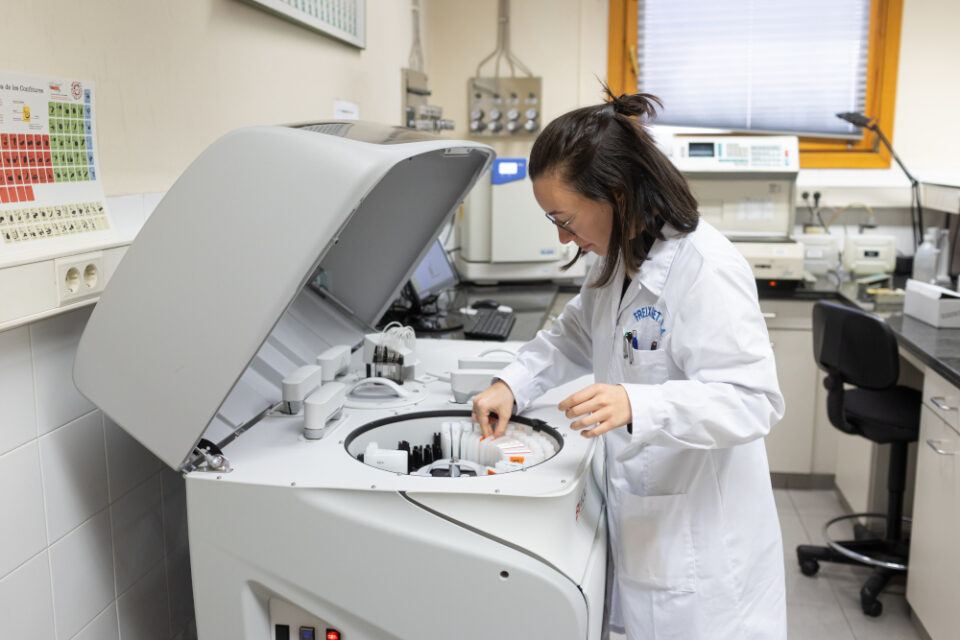

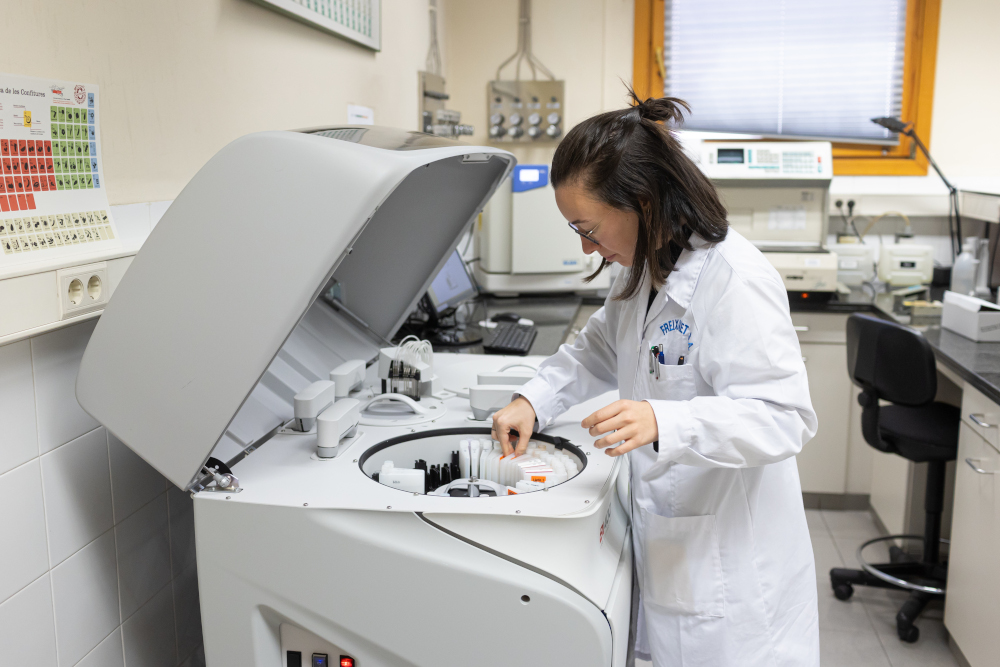

On the other hand, the yeast system that is used is a traditional multiplication system that we feed daily. At the same time, this system is characterized by its technological innovation and works in a fully automated way, thus providing standardization and reliability. Annually, the company produces more than 100 million bottles. In addition, the entire product is made automatically, following the same pattern, so that errors are avoided. The human hand only intervenes in critical processes such as yeast cultivation. The Freixenet Group has a state-of-the-art yeast room that has been built by the company itself and by the engineers who work in it.

Food safety and quality are two fundamental aspects for the company and it is considered that the crop with which it works must be pure. For this reason, the yeasts are introduced into a medium where there is wine and sugar, a place where the material ferments in a controlled way, avoiding undesirable particles. The expedition liquors are introduced into a filter ramp that passes through a membrane that provides purity and prevents any type of contamination. In this sense, the company has the necessary instruments to ensure absolute control of the cultivation, investigate all wines and ensure that contamination of the product is avoided. To guarantee the uniqueness and purity of our indigenous yeast, we also periodically do DNA analysis to ensure that the yeast always stays the same and does not undergo mutations.

Furthermore, the Freixenet Group is a company that exports to more than 140 countries, each with its own requirements and peculiarities. For this reason, the company attaches extreme importance to compliance with international regulations and seeks to merge all the requirements and make the maximum controls to comply with these regulations. In order to cover these controls, the Freixenet Group has its own technology to detect toxic particles that may affect the vineyard and provide a solution.

In this sense, the company makes a commitment to scientific and technological innovation -through the investment in all the necessary resources- that establishes the difference with the rest of competitors and that promotes research and development of new technologies that allow the same thing that was done in the traditional way, but more efficiently and putting sustainability first.

QUALITY CONTROL.

JAUME MARTÍN, QUALITY MANAGER OF GRUPO FREIXENET

The Freixenet Group is a company strong in standardization thanks to its historical commitment to innovation. The firm has been a pioneer in the development of its own and unique technology in the sector, which has been patented by the company and which allows the products to be produced in a more efficient, sustainable, qualitative and safe way. There are models worked by the Freixenet Group that have been exported to the entire sector and that have been a benefit for everyone, as is the case with standardization issues. The company also works together with suppliers to improve processes and materials, a fact that benefits the entire sector.

Regarding the quality control processes, the Freixenet Group applies them from the reception of the raw materials until the product is finished, going through the monitoring during the process and the rest of the phases. The materials used are cork, glass, wine, etc. For this reason, the company has a highly professional and highly qualified team made up of profiles from different fields that ensure the highest quality and food safety.

A clear example that has allowed the company to be positioned as a leader is that it works with very demanding international markets in reference to the subject matter, such as Japan. In order to meet all these demands of each market, the Freixenet Group collaborates with universities in scientific studies. In fact, the research team has a Doctor who has done a thesis on aromas together with the University of Barcelona. This study allows the company to detect the substance that causes the aroma and to develop the products that best suit consumer tastes.

At the same time, the Freixenet Group combines innovation and technology with other more traditional elements, the land and the natural environment, which is the origin of cava and wine.